- Home

- Block Machine

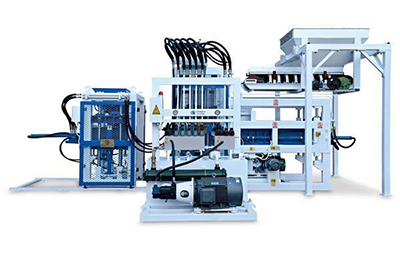

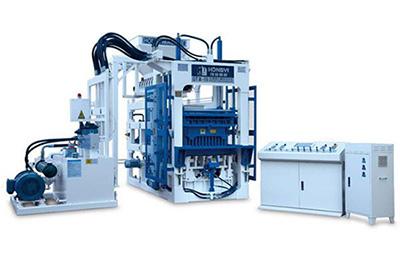

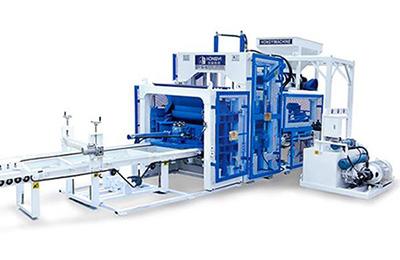

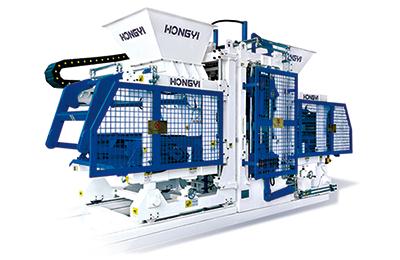

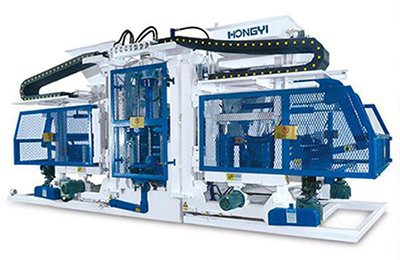

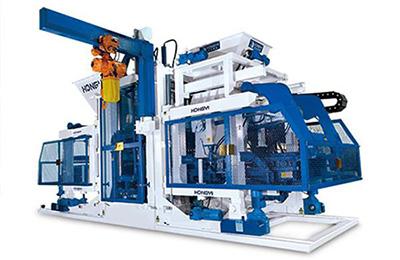

- QTF10-15 Block Making Machine

QTF10-15 Block Making Machine

QTF10-15 is an upgraded version of QT10-15 with an additional movable secondary material distribution system; it has automatic layered material dispensing function and applies to various colorful paving bricks, landscape products and etc.

Features- On the basis of QT10-15 block making machine, a movable material dispensing system is added and it has automatic layered material distributing function.

- The material amount of the surface layer can be adjusted as required to make the brick face beautiful, even and smooth.

- It is applicable for production of various colorful paving bricks, landscape products and etc.

| Overall dimension | 7200×2350×2850mm | Vibration method | Synchronous mode of table & mould |

| Pallet size | 1120×880×45mm(Wooden) /25mm(PVC) | Vibration frequency | 50-70Hz |

| Working area | 1050×800mm | Machine Power | 49.5kW |

| Machine weight | 13800kg | Cycle time | 15s-25s depending on the product size |

| Specification of products (mm) | Number of blocks per palllet | Pieces/hour | Pieces/8 hours | Pieces/300 days (two shifts) | ||

| Block |  | 390×190×190 | 10 | 1,400 | 19,200 | 11,520,000 |

| Hollow Brick |  | 240×115×90 | 24 | 5,760 | 46,080 | 27,648,000 |

| Paving Brick |  | 225×112.5×60 | 24 | 5,760 | 46,080 | 27,648,000 |

| Standard Brick |  | 240×115×53 | 48 | 11,520 | 92,160 | 55,296,000 |

Previously made products

Paving Bricks

Paving Bricks Paving Bricks

Paving Bricks Paving Bricks

Paving Bricks  Paving Bricks

Paving Bricks  Multi-color Paving Bricks

Multi-color Paving Bricks Dutch Bricks

Dutch Bricks Slope Protection Bricks

Slope Protection Bricks Slope Protection Bricks

Slope Protection Bricks Slope Protection Bricks

Slope Protection Bricks Slope Protection Bricks

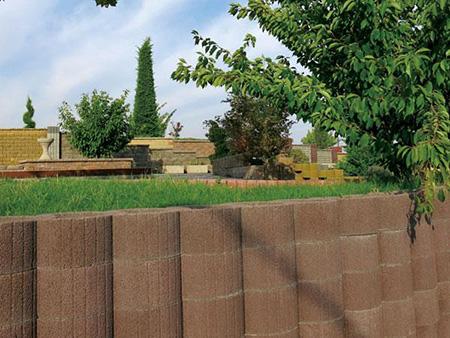

Slope Protection Bricks Shot Blasted Pavers

Shot Blasted Pavers Wall Bricks

Wall Bricks Surface Wall Bricks

Surface Wall Bricks Grass Bricks

Grass Bricks Grass Bricks

Grass Bricks Antique Bricks

Antique Bricks Antique Bricks

Antique Bricks Antique Bricks

Antique Bricks Antique Bricks

Antique Bricks Curb Stones

Curb Stones Curb Stones

Curb Stones Curb Stones

Curb Stones Curb Stones

Curb Stones Flowerpot Bricks

Flowerpot Bricks Flowerpot Bricks

Flowerpot Bricks Flowerpot Bricks

Flowerpot Bricks Flowerpot Bricks

Flowerpot Bricks Colorful Paving Bricks

Colorful Paving Bricks Colorful Paving Bricks

Colorful Paving Bricks