- Home

- EPS Light Weight Wall Panel Production Line

- Vertical EPS Light Wall Panel Production Line

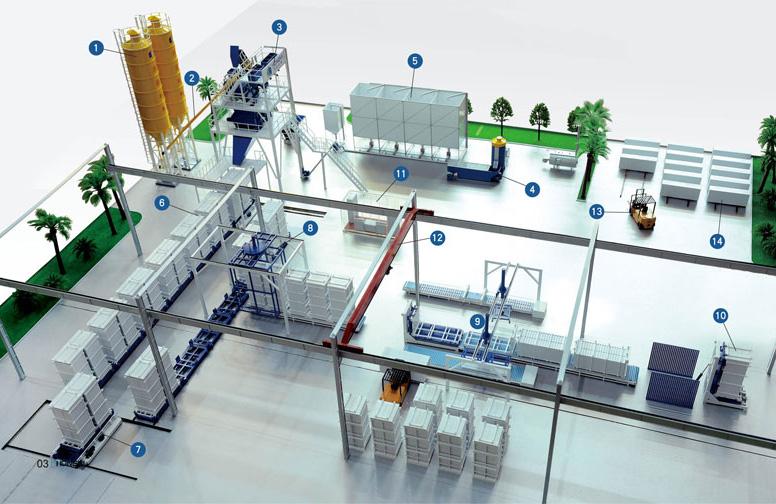

Vertical EPS Light Wall Panel Production Line

The vertical insulated concrete wall panel production line is an enclosed production line adopting automatic batching system, continuous mixing technology, automatic mould vehicle movement, mould tumbler and automatic mould stripping, digital management system and some other technologies to produce products with complete appearance and high precision.

- Cement silo

- Screw conveyor

- Scale

- Batching plant

- Mixings system

- material discharging hopper

- EPS Pre-expander

- EPS silo

- Aggregate measuring bunker

- Controlling room

- Ferry trolley

- Mould car

- Calcium silicate panel inserting platform

- Demoulding travelling crane

The vertical insulated concrete wall panel production line has the following features:

This production line needs smaller floor area than other lines during production.

The injection process can rapidly fill the die cavity with material. Then the material can be easily tamped without hollowing, thus realizing high productivity.

The yield can be increased just by adding the number of mould.

Model and parameters:| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 75 series | 75 | 3000/2440 | 610 | 50±5 | 2 |

| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 90 series | 90 | 3000/2440 | 610 | 55±5 | 4 |

| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 120 series | 120 | 3000/2440 | 610 | 67±5 | 5 |

| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 150 series | 150 | 3000/2440 | 610 | 90±5 | 5 |

| Finished wall panel dimension | 3000/2440×610×75/90/100/120/150/180mm | |

| Wall panel yield of different thickness | 75mm | 46 pieces |

| 90mm | 40 pieces | |

| 100mm | 36 pieces | |

| 120mm | 32 pieces | |

| 150mm | 26 pieces | |

| Dimension | 3560×1560×2865mm | |

| Weight | 3.1T | |

| Item | National standard | Detected index | ||||

| 60mm | 90mm | 120mm | 60mm | 90mm | 120mm | |

| Impact resistance/times | ≥5 | ≥5 | ≥5 | ≥8 | ≥10 | ≥15 |

| Bending breaking load/dead weight multiples | ≥1.5 | ≥1.5 | ≥1.5 | ≥3 | ≥4 | ≥5 |

| Compressive strength | ≥3.5 | ≥3.5 | ≥3.5 | ≥5 | ≥5 | ≥5 |

| Softening coefficient | ≥0.80 | ≥0.80 | ≥0.80 | ≥1 | ≥1 | ≥1 |

| Areal densitykg/m2 | ≤70 | ≤90 | ≤110 | ≤55 | ≤70 | ≤85 |

| Moisture contenta/% | ≤12/10/8 | ≤10/9/7 | ||||

| Drying shrinkage/mm/m | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.45 | ≤0.5 | ≤0.5 |

| Lifting capability/N | ≥1000 | ≥1000 | ≥1000 | ≥1200 | ≥1300 | ≥1300 |

| Noise insulation volume/dB | ≥30 | ≥35 | ≥40 | ≥35 | ≥40 | ≥45 |

| Duration of fire resistance/h | ≥1 | ≥1 | ≥1 | ≥1.5 | ≥3 | ≥4 |

| Heat transfer coefficientb/w/m.k | ≤2 | ≤1.5 | ||||

| Specific radioactivity limitation (solid panel) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Ira internal exposure index/Iraexternal exposure index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |